-40%

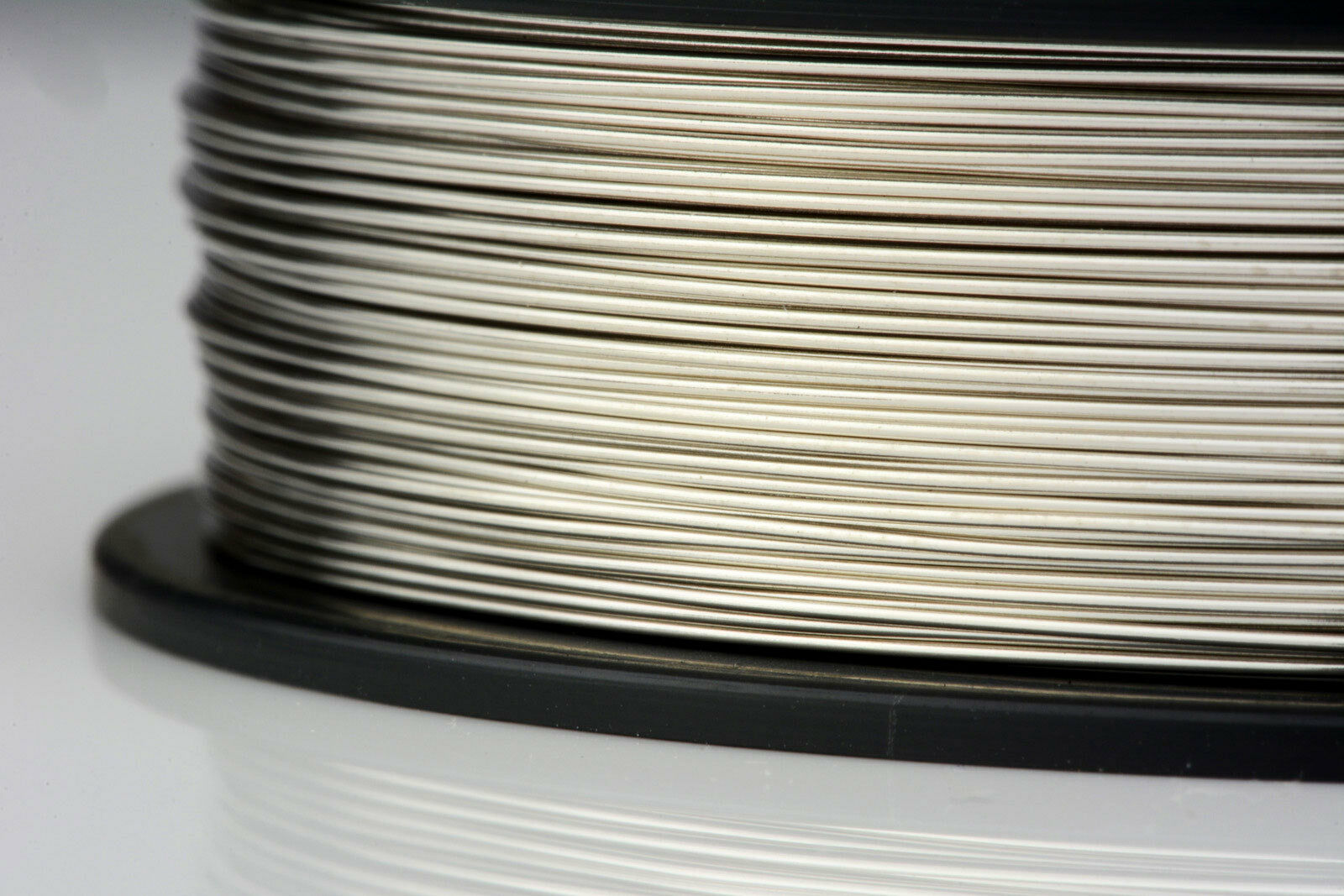

TEMCo Pure Nickel Wire 26 Gauge 500 Ft non resistance AWG Ni200 Nickel 200 ga

$ 13.14

- Description

- Size Guide

Description

Visit Our StoreSpecifications

TEMCo ID:

RW0378

Alloy:

Nickel 200 (Min: 99 Ni, Max: 0.15 C, 0.25 Cu, 0.4 Fe, 0.35 Mn, 0.35 Si, 0.01 S)

Gauge:

26 AWG

Average Wire Diameter:

0.0159 in. (0.40386 mm)

Weight:

6.09 oz

Length:

500 ft

Shape:

Round

Resistance (Ohms/ft @ room temp):

0.2373

Heat treatment:

Annealed (soft)

Melting temperature range:

1400°C (2552°F)

Maximum operating temperature:

1435-1446°C (2615-2635°F)

Curie temperature:

360°C (680°F)

Coefficient of expansion:

13.3 μm/m °C (20 - 100°C)

7.4 x 10-6 in/in °F (70 - 212°F)

Modulus of rigidity:

81 kN/mm² (11748 ksi)

Modulus of elasticity:

204 kN/mm² (29588 ksi)

Density:

0.321 lbs/in³ (8.89 g/cm³)

Tensile strength:

400-500 N/mm² (80,000 min psi, 58-73 ksi

)Specific heat:

456 J/kg • °C (0.109 Btu/lb •°F)

Electrical resistivity:

9.6 ΜW • cm (58 ohm • circ • mil/ft)

Thermal conductivity:

70.2 W/m • ° C (487 btu • in/ft² • h • °F)

data sheet

Download the full specs.

Nickel 200

Nickel 200 is a ferromagnetic, commercially pure (99.6%) wrought Nickel with good mechanical properties over a wide range of temperatures, high ductility, and excellent resistance to many corrosives (in particular hydroxides). Ni 200 is used for a variety of processing equipment, particularly to maintain product purity in handling foods, synthetic fibers and alkalies.

It has roughly the strength of mild steel when annealed and can provide higher strength levels when in the "as rolled" condition. This alloy has a low annealed hardness and very low work-hardening rate that is desirable for cold forming operations such as deep drawing, spinning, coining, etc. It has been used in corrosion-resistant equipment such as caustic evaporators, spun anodes, combustion boats and laboratory crucibles, and electronic components where its excellent fabricating characteristics provide an advantage.

Nickel 200 exhibits good thermal and electrical properties. Its magnetostrictive properties (specifically significant length change when magnetized) make it ideal for use in sonic devices such as sonar or for control in ultrasonic welding.

Applications

Automotive screen and heating elements, lighting and lead wire

Food processing

Synthetic fiber processing (such as production of viscose rayon)

Heat exchangers

Chemical industries

Electrical industries

Manufacturing and handling of sodium hydroxide, particularly at temperatures above 300°C.

Manufacturing of soap.Manufacturing of vinyl chloride monomer.

Reactors and vessels in which fluorine is generated and reacted with hydrocarbons.

Analine hydrochloride production and in the chlorination of aliphatic hydrocarbons such as benzene, methane and ethane.

Electrical and electronic parts.Aerospace and missile components.

Corrosion Resistance

Outstanding

Caustic alkalis up to and including the molten state

Good

Acid, alkaline, and neutral salt solutions. Most useful under reducing conditions.

Not Suitable For

Oxidizing salt solutions.

Can be used at temperatures up to 550°C in dry chlorine and hydrogen chloride. Depending on whether the solution is aerated or not, resistance to mineral acids varies according to temperature and concentration. Corrosion resistance is better in de-aerated acid.

11 Months From Now...

If it doesn't fit.

If it looks funny.

Or you just changed your mind.

Even if it's opened, used or broken, we will still accept your return and pay shipping both ways.

No restocking fee. Up to 1 year.

Free Shipping

To Lower 48 States

Features

Level wound using computerized machiney. 100% quality guarantee.

Properly tensioned. Zero elongation, scratches, or other flaws.

American-made quality. Perfectly drawn.

Our return policy.

If you don't like It, we'll take it back & pay the shipping!

As an OEM, we use many of the products we sell.

As a result only high quality winding materials are offered to you.

Get it FAST.

Most orders received in 2 to 5 days.

Nickel 200 Sizes

Gauge

Ft/lb

Diameter

Ohms/ft @ Room Temp

26 AWG

Ft/Lb.

1313

Diameter

0.0159 in (0.40386 mm)

Ohms/Ft at 68°F

0.2373

28 AWG

Ft/Lb.

2090

Diameter

0.0126 in (0.32004 mm)

Ohms/Ft at 68°F

0.3778

30 AWG

Ft/Lb.

3318

Diameter

0.0100 in (0.25400 mm)

Ohms/Ft at 68°F

0.6

32 AWG

Ft/Lb.

5185

Diameter

0.0080 in (0.20320 mm)

Ohms/Ft at 68°F

0.9375

34 AWG

Ft/Lb.

8364

Diameter

0.0063 in (0.16002 mm)

Ohms/Ft at 68°F

1.511

Comparison Among Other Alloys

Kanthal A1

Composition:

22% Cr

5.8% Al

Fe balance

Maximum Operating

Temperature:

1400°C (2550°F)

Features:

Higher max temp in air

Higher surface load

Higher resistivity

Higher yield strength

Longer life (up to 2-4x that of Nichrome)

Better oxidation properties

Lower density

Better resistance to sulfur

Nichrome 60

Composition:

60% Ni

16% Cr

24% Fe

Maximum Operating

Temperature:

1150°C (2100°F)

Features:

Higher hot and creep strength

Better ductility after use

Higher emissivity

Non-magnetic

Better wet corrosion resistance

Nichrome 80

Composition:

80% Ni

19.5% Cr

1.45% Si

Maximum Operating

Temperature:

1180°C (2150°F)

Features:

Higher hot and creep strength

Better ductility after use

Higher emissivity

Non-magnetic

Better wet corrosion resistance

Nickel 200

Composition:

Min: 99 Ni

Max: 0.15 C, 0.25 Cu

0.4 Fe, 0.35 Mn

0.35 Si, 0.01 S

Maximum Operating

Temperature:*

649°C (1220°F)

Tensile strength and elongation drop significantly above 315°C (600°F). Service temperature is dependent on environment, load and size range.

Features:

Good mechanical properties

Excellent corrosion resistance

Ferromagnetic

High thermal and electrical conductivities

Low gas content vapor pressure

View other Alloys

Kanthal A1

Nichrome 60

Nichrome 80

Nickel 200

Shipping

Domestic

Lower 48 States:

FREE!

Local Pickup Available:

FREE!*

International

Calculated by location.

Orders are usually processed and shipped within 24 to 48 hours of receipt of your payment. Please provide us with a physical shipping address (failing to do so may delay your order). We may ship an order by a different courier at our discretion. If you need to receive an order within a guaranteed time frame, please contact us for rush options and expedited shipping.

Import duties, taxes, and charges are not included in the item price or shipping charges. These charges are the buyer's responsibility. Please check with your country's customs office to determine what these additional costs will be prior to bidding/buying. Furthermore, we will not mark merchandise values below value or mark items as "Gifts".

*Local Pick Up

is available at our Fremont CA location, Monday through Friday 9:00 a.m. to 5:00 p.m. Please contact us ahead to ensure that your item is in stock at our location before pick-up.

** International Buyers, Please Note:

If shipping for your country is not listed,

contact us

for details.

Payment & Returns

Payment

TEMCo accepts the following payment methods: PayPal, Visa, MasterCard, AMEX, Discover.

We charge 9.75% sales tax for all orders shipping within California. Tax exemption is available if we are provided with a valid California resale certificate.

Returns

TEMCo allows for the return of new and unused products in original factory condition and used defective products for 30 days from the date of purchase. Returns must be pre-approved by TEMCo and have a return merchandise authorization (RMA) number issued by TEMCo. Unauthorized returns will not be accepted.

We recommend using a shipping carrier with online tracking and insurance. TEMCo will replace the item with an identical item, issue a full store credit for the value of the item, or issue a refund for the value of the item, minus a 20% restocking fee. Items with a 100% satisfaction guarantee are exempt from the 20% restocking fee.

Customer feedback

We strive to provide 5-star service. Shop with confidence!

100% Positive reviews

We want nothing more for our buyers than to be 100% happy with their purchase. We strive to earn a 5-star rating from every purchase. When you receive your purchase, please take a moment to leave us a positive feedback. If there was something unsatisfactory about your purchase, please

contact us

before leaving feedback and we'll do what's necessary to remedy the problem and ensure your satisfaction!

When your order ships from our warehouse, we will automatically leave you positive feedback.

"I have always been delighted with the service from TEMCo."

Your customer service, which is seldom needed, is wonderful, the staff knowledgeable and courteous. The shipping has been quite fast, which make my life easier... So, thank you, for the good experiences with the company!

Rick C

"I have ordered from TEMCo several times over the last 2 years and have always found the process to be simple and quick."

Making the order takes only a few moments, the product is always high quality and the shipping fast.

Glen B

"Thank you for a very satisfying and honest transaction."

It is really great to deal with a company that does exactly what they advertise. I can truly say I would recommend your company to anyone interested in the equipment you sell.

Paul Gilley

"The service was awesome."

I had many tech questions, and they spent about 30 mins on the phone answering all of them for me. It is not to often to find service like that!!!!! I am so happy and will definitly purchase from them again. A+++++

MRZ Contracting

Still not sure about us?

Check us out on the

Better Business Bureau

and

Reseller Ratings

, or look at our

eBay seller ratings

with a perfect score in all categories.

View our other products

Battery Link Cables

Motor Capacitors

Electric Motors

Lighting

magnet wire

motor starters

Phase converters

raw material

resistance wire

ring terminals

SO Cord

Solar Tools & Hardware

switches & Relays

tools

valves

drives

welding cable

About TEMCo

Since 1968, TEMCo has become a trusted name in industrial power products.

TEMCo products meet the demands of tough industrial applications with dependability and quality. We are proud to be an accredited member of the Better Business Bureau Online Reliability Program. Some of our customers include:

TEMCo Industrial

Sales, Manufacturing & Distribution

48621 Warm Springs Blvd

Fremont, CA 94539

Contact us

Send us a Message